How much power does mining use?

The mining industry is one of the most energy-intensive sectors in the world. From excavation and hauling to processing and ventilation, nearly every operation depends heavily on a stable and robust power supply. For remote and large-scale mining projects, accessing reliable grid power is often not an option. This is where the critical need for continuous power for mining operations comes into play—making on-site power generation not just an alternative, but a necessity.

Understanding the Energy Demand in Mining

Mining operations consume vast amounts of electricity. Key energy-consuming processes include:

Drilling, Blasting, and Cutting: Heavy machinery such as continuous miners, drills, and excavators require significant power to break down rock and mineral structures.

Material Handling: Conveyor belts, hoists, and shovel trucks operate almost non-stop, moving tonnes of material each hour.

Processing: Crushing, grinding, and separating minerals are highly energy-intensive steps that often account for the largest share of a mine’s electricity usage.

Support Systems: Ventilation, cooling, water pumping, and lighting are essential for both safety and functionality, further adding to the energy load.

It’s not uncommon for a single large-scale mine to use as much electricity as a small city. This sheer scale of consumption underscores the importance of a resilient power infrastructure.

The Financial and Operational Impact of Power Consumption

High energy usage directly influences operational costs and profitability. Interruptions or power failures can lead to:

Production halts, resulting in substantial revenue loss per hour.

Equipment downtime and increased maintenance costs.

Safety hazards, especially in underground operations where ventilation is critical.

These risks highlight why it’s essential to have not just adequate power, but uninterrupted and high-quality power. A well-designed continuous power for mining operations system helps mitigate financial and operational vulnerabilities.

Why Continuous Power Is Non-Negotiable in Mining

In mining, any interruption in electricity can bring the entire operation to a standstill. Unlike many other industries, mining cannot rely on stop-start power sources. Key reasons include:

Safety Requirements: Systems like ventilation and gas monitoring must operate 24/7 to ensure a safe working environment.

Equipment Longevity: Consistent voltage and frequency prevent damage to sensitive and expensive mining machinery.

Process Continuity: Many mining processes, especially mineral processing, are designed to run continuously. Any break can require lengthy and costly restarts.

This is why more mining companies are turning to dedicated on-site power generation solutions to ensure continuous power for mining operations without reliance on unstable grids.

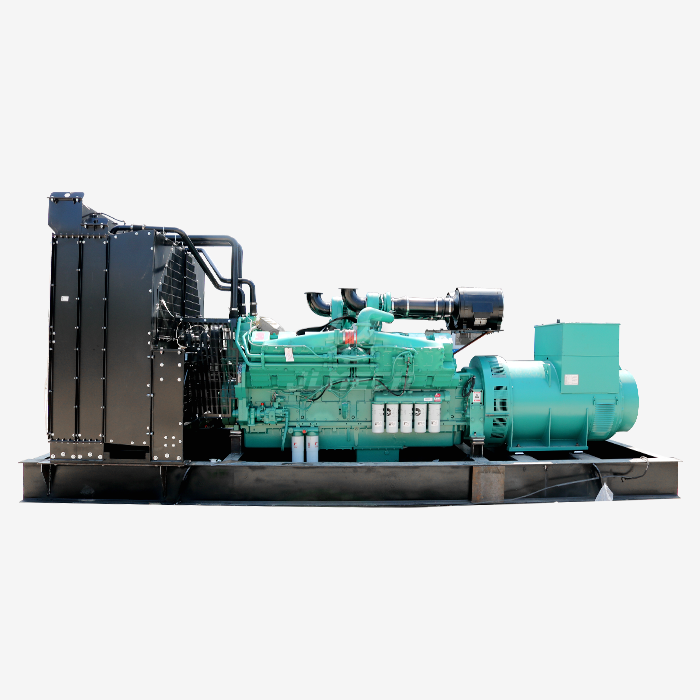

Diesel Generators: The Backbone of Reliable Mining Power

When it comes to delivering robust and uninterrupted electricity in remote or off-grid mining locations, diesel generators remain the technology of choice. Here’s why:

High Power Output: Diesel generators can deliver the high megawatt-level capacities required by heavy mining equipment.

Durability: Built to perform under extreme conditions including dust, temperature variations, and altitude.

Quick Ramp-Up: They can start and reach full load rapidly, supporting sudden energy demands.

Fuel Storage and Availability: Diesel can be stored safely on-site for extended periods, reducing dependency on continuous fuel delivery.

For mines where reliability is paramount, diesel generator sets represent the most practical solution for delivering continuous power for mining operations.

Conclusion

The question isn’t just how much power mining uses—it’s how reliably that power can be delivered. In an industry where downtime translates directly into financial loss and safety risks, there is no room for power interruptions. Investing in a resilient power infrastructure is not an option; it is a operational imperative.

Ensuring continuous power for mining operations requires robust engineering, high-quality equipment, and strategic planning. This is where experienced power solution providers add critical value.

Partner with JLMECH for Your Mining Power Needs

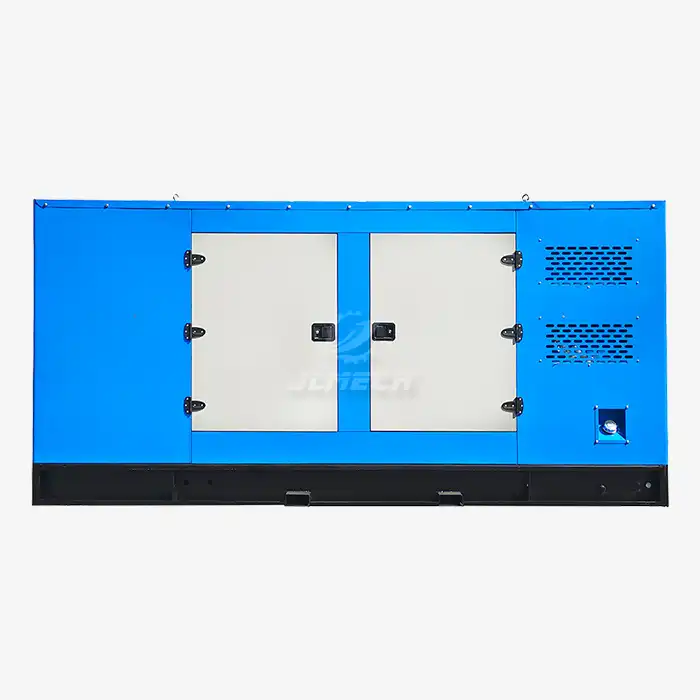

At JLMECH, we specialize in delivering high-performance diesel generators engineered for the most demanding mining environments. With decades of expertise and a firm commitment to quality, we help mining companies worldwide maintain productivity and safety through uninterrupted power supply.

Our team offers:

Customized power solutions tailored to specific mine requirements.

Generators built for durability, efficiency, and ease of maintenance.

End-to-end support from planning and installation to service and parts.

Reach out to our energy experts to discuss your project needs:

Email: skala@whjlmech.com

Let us help you design a power system that guarantees reliability, safety, and efficiency for your mining operations.

References

International Energy Agency. (2023). Energy Consumption in Mining and Minerals Processing. IEA Publications.

MacDonald, L. (2022). Power System Design for Remote Mining Sites. Mining Engineering Journal, 34(4), 56-67.

U.S. Department of Energy. (2021). Best Practices for Diesel Power Generation in Industrial Applications. DOE Technical Reports.

Roberts, S., & Nielsen, T. (2022). The True Cost of Power Interruptions in Large-Scale Mining. Resources Policy, 75, 101521.

Carlson, E. (2023). Advances in Diesel Engine Efficiency for Heavy Industries. Power Systems Engineering, 28(2), 44-58.

VIEW MORE60Hz industrial diesel generator

VIEW MORE60Hz industrial diesel generator VIEW MORESilent generator 30kVA

VIEW MORESilent generator 30kVA VIEW MORECummins Diesel Engine /Generator

VIEW MORECummins Diesel Engine /Generator VIEW MOREDirect injector diesel engine generator

VIEW MOREDirect injector diesel engine generator VIEW MOREMaximum power 3000KW generator

VIEW MOREMaximum power 3000KW generator VIEW MORE150kva perkins diesel generator

VIEW MORE150kva perkins diesel generator VIEW MOREweichai diesel power generator

VIEW MOREweichai diesel power generator VIEW MOREdiesel generator set 100kva

VIEW MOREdiesel generator set 100kva