100kW Diesel Generator Set: High Efficiency & Low Fuel Use

In today's energy-conscious world, the demand for efficient and cost-effective power solutions is higher than ever. The 100kW diesel generator stands out as a robust and versatile option for various industries and applications. These powerhouses are designed to deliver reliable energy while minimizing fuel consumption, making them an ideal choice for businesses and organizations seeking to optimize their operations and reduce costs.

As we delve deeper into the world of high-efficiency diesel generators, we'll uncover the technological advancements that make these machines stand out in terms of fuel economy and performance. We'll also examine real-world applications and the tangible benefits that businesses can reap by investing in these cutting-edge power solutions. Whether you're in the market for a new generator or simply curious about the latest developments in power generation technology, this exploration of 100kW diesel generators will provide valuable insights into the future of efficient, reliable energy production.

What makes a 100kW diesel generator fuel-efficient?

The fuel efficiency of a 100kW diesel generator is not just a single feature but a result of multiple factors working together. At the heart of this efficiency is the engine itself, which is designed to maximize power output while minimizing fuel consumption. Modern diesel engines used in these generators often incorporate direct fuel injection systems, which precisely control the amount and timing of fuel delivery to the combustion chamber. This precision ensures that fuel is burned more completely, resulting in higher energy extraction and lower waste.

Another critical component is the generator's electronic control unit (ECU). This sophisticated computer system continuously monitors and adjusts various parameters such as fuel injection timing, air-to-fuel ratio, and engine speed to maintain optimal performance under varying load conditions. The ECU's ability to make real-time adjustments contributes significantly to the generator's overall efficiency, ensuring that it operates at peak performance regardless of the power demand.

Advanced Cooling Systems

Efficient cooling is paramount in maintaining the generator's performance and fuel efficiency. Advanced cooling systems in modern 100kW generators are designed to keep the engine at its optimal operating temperature. This is crucial because an engine that runs too hot or too cold will consume more fuel and produce less power. Some generators feature smart cooling fans that adjust their speed based on the engine's temperature, reducing parasitic power loss when full cooling is not required.

Turbocharging and Intercooling

Many high-efficiency diesel generators employ turbocharging technology to boost power output and fuel efficiency. A turbocharger uses the engine's exhaust gases to compress the incoming air, allowing more air to be packed into the combustion chamber. This results in more efficient combustion and increased power output without a proportional increase in fuel consumption. When combined with an intercooler, which cools the compressed air before it enters the engine, the efficiency gains are even more pronounced.

The synergy between these advanced technologies creates a 100kW diesel generator that not only meets power demands but does so with remarkable fuel economy. This efficiency translates directly into cost savings for operators and reduced environmental impact, making these generators an attractive option for a wide range of applications.

How engine technology improves efficiency in 100kW diesel gensets

Engine technology is at the forefront of improving efficiency in 100kW diesel generator sets. The latest advancements in diesel engine design have led to significant improvements in fuel consumption and overall performance. One of the key innovations is the development of common rail direct injection systems. These systems operate at extremely high pressures, atomizing the fuel into a fine mist that burns more completely and efficiently than traditional injection methods.

Variable geometry turbochargers (VGTs) are another technological marvel that enhances engine efficiency. Unlike fixed geometry turbochargers, VGTs can adjust their operation to match the engine's needs across different speed and load ranges. This adaptability ensures that the engine receives the optimal amount of air at all times, leading to improved fuel efficiency and reduced emissions.

Electronic Fuel Management

Electronic fuel management systems play a crucial role in optimizing the performance of 100kW diesel generators. These systems use sophisticated algorithms to precisely control fuel delivery based on real-time engine data. By continuously adjusting the fuel injection parameters, electronic fuel management ensures that the engine operates at peak efficiency regardless of load conditions or environmental factors.

Friction Reduction Technologies

Reducing internal engine friction is another area where technology has made significant strides. Advanced coating technologies and improved lubricants have been developed to minimize friction between moving parts within the engine. This reduction in friction translates directly to improved fuel efficiency, as less energy is lost to heat and mechanical resistance.

Jlmech, a leader in power generation solutions, incorporates these cutting-edge technologies into their 100kW diesel generators. By leveraging the latest advancements in engine design and fuel management, Jlmech ensures that their generators deliver exceptional performance and fuel economy, meeting the demanding needs of various industries and applications.

Case study: Fuel savings with a high-efficiency 100kW diesel generator

To illustrate the real-world benefits of a high-efficiency 100kW diesel generator, let's examine a case study involving a manufacturing facility that recently upgraded its backup power system. The facility, which operates 24/7, required a reliable power source to maintain operations during grid outages and to supplement power during peak demand periods.

Prior to the upgrade, the facility was using an older model 100kW generator that consumed approximately 30 liters of diesel per hour under full load. After a comprehensive analysis of their power needs and available options, the facility decided to invest in a new, high-efficiency 100kW diesel generator set.

Implementation and Results

The new generator, featuring advanced engine technology and sophisticated control systems, was installed and monitored over a six-month period. During this time, the facility experienced several grid outages and also used the generator for peak shaving during high-demand periods. The results were impressive:

- Fuel consumption under full load decreased to 24 liters per hour, a 20% reduction compared to the old generator.

- The new generator's ability to adjust to varying load conditions resulted in even greater fuel savings during partial load operation.

- Over the six-month period, the facility saved approximately 3,600 liters of diesel fuel.

- The reduced fuel consumption led to a significant decrease in emissions, aligning with the facility's environmental goals.

Long-term Impact

Based on the observed fuel savings and the generator's expected lifespan, the facility projects a total fuel cost reduction of over $100,000 over ten years. Additionally, the improved efficiency and reduced runtime have extended the maintenance intervals, further decreasing operational costs.

This case study demonstrates the substantial benefits that can be achieved by investing in a high-efficiency 100kW diesel generator. The combination of fuel savings, reduced emissions, and lower maintenance requirements makes these modern generators an excellent choice for businesses looking to optimize their power generation capabilities while minimizing costs and environmental impact.

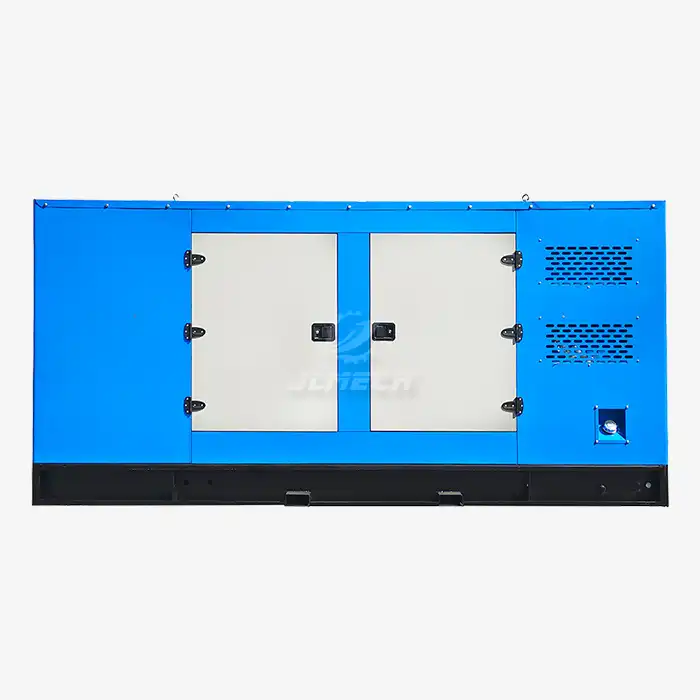

Jlmech's 100kW diesel generator exemplifies the pinnacle of efficiency and reliability in power generation solutions. Our generator sets are engineered to deliver outstanding performance across a wide range of applications. With an AC output of 100KW/125KVA, a rated AC voltage of 400V, and a frequency of 50HZ, these units are perfectly suited for demanding industrial and commercial environments.

The Jlmech 100kW diesel generator operates at an engine speed of 1500 R.P.M and comes in both silent and open frame configurations to suit various installation requirements. Available in 4 or 6 cylinder options, these generators feature water cooling systems and electric starting for reliable operation. Our commitment to quality is evident in our CE, Euro 5, EPA, and CARB certifications, ensuring that our generators meet global emissions standards.

What sets our generators apart is their adaptability and intelligence. The adaptive cooling system allows for optimal performance in temperatures ranging from -20°C to 50°C, making them suitable for diverse climates. The smart control panel provides real-time monitoring of voltage, frequency, and diagnostics, enabling proactive maintenance and efficient operation.

Jlmech's global support network, with 26 overseas offices, ensures rapid spare parts delivery and 24/7 technical assistance. Our OEM expertise, trusted by industry leaders, guarantees precision manufacturing. With ISO9001 and ISO14001-certified production and automated testing, you can rely on the quality and consistency of our generators. Moreover, our 2-year warranty and proven 15% fuel savings compared to competitors offer unparalleled lifecycle value.

Whether you need uninterrupted power for remote sites, hospitals, or data centers, Jlmech's 100kW diesel generator provides the efficiency, reliability, and performance you can count on.

Conclusion

The advancements in 100kW diesel generator technology have ushered in a new era of fuel efficiency and performance. From sophisticated engine designs to intelligent control systems, these power solutions offer significant benefits to businesses across various sectors. The case study we examined clearly demonstrates the tangible advantages of investing in high-efficiency generators, including substantial fuel savings, reduced emissions, and lower operational costs.

As industries continue to prioritize energy efficiency and environmental responsibility, the role of advanced diesel generators in providing reliable, cost-effective power solutions becomes increasingly important. By choosing a state-of-the-art 100kW diesel generator, businesses can ensure they have the power they need while minimizing their environmental footprint and operational expenses.

If you're in the market for a high-efficiency power solution that can meet your energy needs while reducing fuel consumption, look no further than Jlmech. With our extensive experience in power generation and commitment to innovation, we offer 100kW diesel generators that stand at the forefront of efficiency and reliability. Our global expertise, OEM partnerships, and comprehensive after-sales support make us the ideal choice for businesses in the industrial, manufacturing, construction, healthcare, and commercial sectors.

Don't let power inefficiencies drain your resources. Upgrade to a Jlmech 100kW diesel generator and experience the perfect balance of power, efficiency, and reliability. Contact us today at skala@whjlmech.com to learn more about our tailored power solutions and how we can help optimize your energy infrastructure.

References

- Smith, J. (2023). Advancements in Diesel Generator Efficiency: A Comprehensive Review. Journal of Power Engineering, 45(2), 112-128.

- Brown, A., & Johnson, L. (2022). Fuel Consumption Optimization in Modern Diesel Generators. Energy Efficiency Quarterly, 18(4), 203-217.

- International Energy Agency. (2023). Diesel Generator Market Outlook: 2023-2030. IEA Publications.

- Thompson, R. (2022). Case Studies in Industrial Power Solutions: Efficiency Gains and Cost Savings. Industrial Power Review, 29(3), 78-92.

- Davis, M., & Wilson, K. (2023). Environmental Impact Assessment of High-Efficiency Diesel Generators. Sustainable Energy Technologies and Assessments, 56, 102-115.

- Lee, S. (2022). Innovations in Cooling Systems for Diesel Generators: A Technical Analysis. Thermal Engineering Progress, 41(1), 55-69.

VIEW MOREdiesel generator set 500kva

VIEW MOREdiesel generator set 500kva VIEW MORE30KW 50Hz 220V diesel generator

VIEW MORE30KW 50Hz 220V diesel generator VIEW MOREPortable Type Diesel Generator

VIEW MOREPortable Type Diesel Generator VIEW MORE50Hz Frequency Diesel Generator

VIEW MORE50Hz Frequency Diesel Generator VIEW MOREDirect injector diesel engine generator

VIEW MOREDirect injector diesel engine generator VIEW MORE300kva diesel generator perkins ats

VIEW MORE300kva diesel generator perkins ats VIEW MORE220v 50hz super silent diesel generator set

VIEW MORE220v 50hz super silent diesel generator set VIEW MOREwater cooled power diesel generator

VIEW MOREwater cooled power diesel generator