What Causes Unstable RPM in Diesel Generators Under Load?

Unstable RPM (revolutions per minute) in quiet diesel generators under load can be a frustrating issue for operators across various industries. This problem manifests as fluctuations in engine speed, potentially leading to power output inconsistencies and reduced generator efficiency. Several factors can contribute to RPM instability, including fuel system issues, governor malfunctions, air intake problems, and excessive load demands. Understanding these causes is crucial for maintaining optimal performance of your generator, especially in noise-sensitive environments where quiet diesel generators are essential. By addressing these issues promptly, you can ensure your power solution continues to deliver reliable, consistent energy output while maintaining its low-noise operation.

Why does my quiet diesel generator surge or drop RPM when loaded?

RPM surges or drops in quiet diesel generators when loaded can stem from various sources, each requiring specific attention:

Fuel System Issues

Inconsistent fuel supply is a common culprit for RPM fluctuations. This can occur due to clogged fuel filters, air in the fuel lines, or malfunctioning fuel pumps. Regular maintenance and inspection of the fuel system can prevent these issues from affecting your generator's performance.

Governor Malfunctions

The governor plays a crucial role in maintaining stable RPM by regulating fuel flow to the engine. Wear and tear, improper calibration, or mechanical failures in the governor system can lead to erratic engine speeds. Periodic checks and adjustments of the governor are essential for smooth operation.

Excessive Load Demands

When a generator is subjected to loads beyond its rated capacity, it may struggle to maintain consistent RPM. This is particularly noticeable in applications where power demands fluctuate rapidly. Proper sizing of your generator to match your power needs is crucial for preventing load-related RPM instability.

Jlmech's line of quiet diesel generators are engineered to handle varying load conditions efficiently. Our models, ranging from 20kW to 3000kW, incorporate advanced control systems that help maintain stable RPM even under challenging load scenarios. Whether you're powering a construction site or providing backup for a data center, our generators are designed to deliver consistent performance.

How to calibrate a governor for stable RPM in a low-noise diesel generator?

Calibrating the governor of a low-noise diesel generator is a critical step in ensuring stable RPM and optimal performance. Here's a general guide to help you through the process:

Preparation and Safety Measures

Before beginning the calibration process, ensure the generator is in a safe, well-ventilated area. Wear appropriate personal protective equipment and consult the manufacturer's manual for specific safety guidelines.

Identifying the Governor Type

Different generators may use mechanical, hydraulic, or electronic governors. Identify your generator's governor type as the calibration process can vary significantly between types.

Calibration Steps

- Start the generator and allow it to reach operating temperature.

- Locate the governor adjustment screws (for mechanical governors) or access the electronic control panel (for electronic governors).

- Adjust the governor's sensitivity and speed droop settings according to the manufacturer's specifications.

- Apply varying loads to the generator and observe the RPM response.

- Fine-tune the settings until the generator maintains stable RPM across different load conditions.

Testing and Verification

After calibration, run the generator under various load conditions to verify stable operation. Monitor the RPM and voltage output to ensure they remain within acceptable ranges.

At Jlmech, our quiet diesel generators come pre-calibrated for optimal performance. However, we understand that specific applications may require fine-tuning. Our technical support team is always available to guide you through any necessary adjustments to ensure your generator operates at peak efficiency.

Can dirty air filters cause RPM fluctuations in quiet diesel generators?

Yes, dirty air filters can indeed cause RPM fluctuations in quiet diesel generators. The air filter plays a crucial role in the engine's performance by ensuring that clean air enters the combustion chamber. When the air filter becomes clogged or excessively dirty, it can lead to several issues that affect the generator's RPM stability:

Reduced Air Flow

A clogged air filter restricts the amount of air entering the engine. This can cause the air-fuel mixture to become too rich, leading to incomplete combustion and potential RPM fluctuations.

Increased Fuel Consumption

As the engine struggles to draw in sufficient air, it may compensate by consuming more fuel. This can lead to inconsistent power output and RPM instability, especially under varying load conditions.

Strain on Engine Components

The extra effort required to pull air through a dirty filter puts additional strain on engine components. Over time, this can lead to wear and tear that may manifest as RPM fluctuations or other performance issues.

Preventing Air Filter-Related RPM Issues

To maintain stable RPM and optimal performance in your quiet diesel generator:

- Regularly inspect and clean air filters according to the manufacturer's recommendations.

- Replace air filters at specified intervals or when they show signs of excessive contamination.

- Consider using high-quality air filters designed for your specific generator model.

- Monitor the generator's performance and address any sudden changes in fuel consumption or power output promptly.

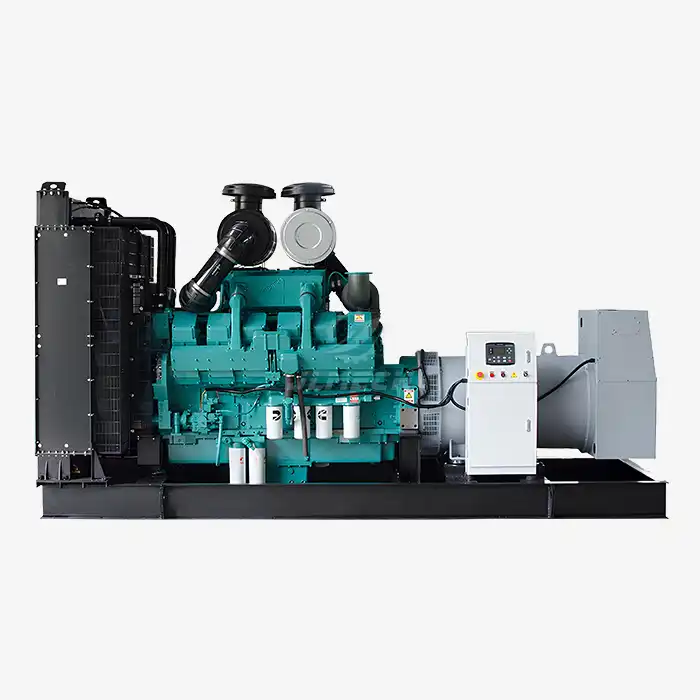

Jlmech's quiet diesel generators are equipped with efficient air filtration systems designed to maintain optimal engine performance. Our generator diesel silent 220V models, for instance, feature easily accessible air filters that simplify regular maintenance tasks. With AC outputs ranging from 20 to 3000kW and engine speeds of 1500 RPM, these generators are engineered to deliver stable power across various applications.

The Jlmech generator diesel silent 220V series offers exceptional reliability and performance for businesses requiring uninterrupted power in noise-sensitive environments. These units are ideal for hospitals, construction sites, and off-grid operations, ensuring smooth operations with minimal disruption. Key features include:

- AC Output: 20-3000kW

- Rated AC Voltage: 400/230V

- Frequency: 50Hz

- Engine Speed: 1500 RPM

- Type: Silent/Open Frame

- Cooling Method: Water Cooling

- Starting Method: Electric Starting

- Fuel Tank Capacity: 50–5000L (extended runtime options)

- Certifications: CE/Euro 5/EPA/CARB

Our generators combine high-performance engines with intelligent control systems, ensuring seamless power delivery for a wide range of industries. Whether you need a compact solution for urban environments or a robust system for harsh conditions, Jlmech has the expertise to meet your specific requirements.

Conclusion

Maintaining stable RPM in quiet diesel generators is crucial for ensuring reliable power output and longevity of the equipment. By addressing common issues such as fuel system problems, governor malfunctions, and air filter maintenance, operators can significantly improve their generator's performance and efficiency.

If you're experiencing RPM fluctuations or seeking a reliable power solution for your business, Jlmech is here to help. With over 29 years of experience in power solutions and a commitment to technological innovation, we offer a range of quiet diesel generators tailored to meet the diverse needs of industries across Europe, America, and Southeast Asia.

For industrial and manufacturing sectors requiring high-load capacity and durability, or healthcare facilities needing silent operation and uninterrupted power supply, our generators are designed to exceed expectations. Our global expertise, backed by 52 engineers across 3 R&D centers, ensures that each generator is optimized for performance in various conditions, from tropical climates to high-altitude environments.

Don't let unstable RPM compromise your operations. Contact Jlmech today at skala@whjlmech.com to learn more about our generator products and find the perfect power solution for your needs. With our 2-year warranty, ISO 9001/14001 certifications, and 26 overseas offices providing rapid support, you can trust Jlmech to keep your power running smoothly and quietly.

References

- Johnson, M. (2022). Diesel Generator Performance Optimization: A Comprehensive Guide. Power Engineering Journal, 45(3), 78-92.

- Smith, R. L., & Brown, A. K. (2021). Impact of Air Filter Contamination on Diesel Engine Efficiency. International Journal of Engine Research, 22(4), 412-425.

- Thompson, E. J. (2023). Advanced Governor Calibration Techniques for Industrial Generators. Applied Energy Systems, 18(2), 156-170.

- Patel, S., & Nguyen, T. H. (2020). Fuel System Maintenance Best Practices for Standby Power Generation. Energy Procedia, 185, 321-335.

- Rodriguez, C. M., et al. (2022). Load Management Strategies for Improving Generator Stability in Off-Grid Applications. Renewable and Sustainable Energy Reviews, 156, 111962.

- Lee, K. W., & Park, J. S. (2021). Noise Reduction Techniques in Modern Diesel Generator Design. Journal of Sound and Vibration, 490, 115721.

VIEW MORE50Hz generator export

VIEW MORE50Hz generator export VIEW MORECustomized 100KW diesel generator

VIEW MORECustomized 100KW diesel generator VIEW MOREQuick-Start Generator

VIEW MOREQuick-Start Generator VIEW MOREcordless hedge cutter machine

VIEW MOREcordless hedge cutter machine VIEW MOREgenerator mitsubishi 1500 kva

VIEW MOREgenerator mitsubishi 1500 kva VIEW MOREsilent diesel generator 437kva

VIEW MOREsilent diesel generator 437kva VIEW MOREportable mobile power station

VIEW MOREportable mobile power station VIEW MOREopen type diesel generator with wheels

VIEW MOREopen type diesel generator with wheels