How does fuel consumption vary with diesel generator load capacity?

Understanding the relationship between fuel consumption and load capacity is crucial for optimizing the performance of a 220v diesel generator. Fuel consumption in diesel generators varies significantly depending on the load capacity, directly impacting operational costs and efficiency. Generally, as the load on a generator increases, fuel consumption rises, but not in a linear fashion.

This variability in fuel consumption across different load capacities underscores the importance of proper sizing when selecting a diesel generator. An oversized generator running at low loads will consume more fuel per kilowatt-hour produced, while an undersized unit forced to run at near-maximum capacity will suffer from reduced efficiency and increased wear. Therefore, understanding your power needs and matching them to the appropriate generator capacity is essential for optimizing fuel consumption and overall performance.

Does a 220v diesel generator use less fuel at 50% load?

Yes, a 220v diesel generator typically uses less fuel per kilowatt-hour produced when operating at around 50% load compared to lower or higher load percentages. This phenomenon is due to the engine's optimal efficiency range, which for most diesel generators falls between 50% and 75% of their rated capacity.

At 50% load, several factors contribute to improved fuel efficiency:

Optimal Combustion Efficiency

Diesel engines are designed to operate most efficiently within a specific load range. At 50% load, the combustion process is often at its most efficient, allowing for complete fuel burning and minimal waste.

Reduced Mechanical Losses

Operating at moderate loads reduces friction and other mechanical losses compared to running at very low or very high loads. This contributes to overall improved efficiency.

Balanced Heat Management

At 50% load, the generator's cooling system can effectively manage heat production, maintaining optimal operating temperatures without overworking the cooling components.

However, it's important to note that while 50% load often represents a sweet spot for fuel efficiency, the exact optimal load can vary depending on the specific generator model and design. Some modern generators are engineered to maintain high efficiency across a broader range of loads.

How to calculate diesel generator fuel usage per kWh?

Calculating the fuel usage per kilowatt-hour (kWh) for a diesel generator is essential for understanding its efficiency and operational costs. Here's a step-by-step guide to perform this calculation:

Step 1: Measure Fuel Consumption

First, determine the amount of fuel consumed over a specific period. This can be done by measuring the fuel tank level before and after running the generator for a set time, or by using a fuel flow meter if available.

Step 2: Determine Power Output

Measure the electrical power output of the generator during the same period. This is typically done using a power meter that measures kilowatt-hours (kWh) produced.

Step 3: Calculate Fuel Consumption Rate

Divide the amount of fuel consumed by the time period to get the fuel consumption rate in liters per hour (L/h) or gallons per hour (gal/h).

Step 4: Calculate Power Output Rate

Divide the total kWh produced by the time period to get the power output rate in kW.

Step 5: Compute Fuel Usage per kWh

Divide the fuel consumption rate by the power output rate to get the fuel usage per kWh. The formula is:

Fuel Usage per kWh = Fuel Consumption Rate (L/h) / Power Output Rate (kW)

For example, if a 220v diesel generator consumes 20 liters of fuel in 4 hours while producing 160 kWh:

Fuel Consumption Rate = 20 L / 4 h = 5 L/h

Power Output Rate = 160 kWh / 4 h = 40 kW

Fuel Usage per kWh = 5 L/h / 40 kW = 0.125 L/kWh

This calculation allows you to compare the efficiency of different generators or assess the impact of varying loads on fuel efficiency.

Optimal load percentage for fuel-efficient 220v diesel generators

Determining the optimal load percentage for fuel-efficient operation of a 220v diesel generator is crucial for maximizing performance and minimizing operational costs. While the exact optimal load can vary depending on the specific generator model and design, there are general guidelines that apply to most diesel generators:

The 70-80% Rule

For many diesel generators, the optimal load percentage for fuel efficiency falls between 70% and 80% of the generator's rated capacity. This range typically offers the best balance between power output and fuel consumption.

Factors Influencing Optimal Load

Several factors can affect the optimal load percentage for a diesel generator:

- Generator Design: Modern generators may be optimized for efficiency across a wider load range.

- Engine Type: Different engine designs may have varying optimal load points.

- Ambient Conditions: Temperature and altitude can affect generator performance and optimal load.

- Fuel Quality: Higher quality fuel can improve efficiency and may shift the optimal load range.

Avoiding Underloading

Operating a diesel generator at loads below 30-40% of its rated capacity can lead to several issues:

- Increased fuel consumption per kWh produced

- Carbon build-up in the engine

- Wet stacking (unburned fuel accumulating in the exhaust system)

- Reduced engine lifespan

To maximize fuel efficiency and generator longevity, it's crucial to size your generator appropriately for your power needs, aiming to operate it within its optimal load range as much as possible.

Jlmech, a leading manufacturer of diesel generators, understands the importance of load optimization in generator performance. Their range of 220v diesel generators is designed to maintain high efficiency across various load conditions, catering to diverse power needs while ensuring optimal fuel consumption.

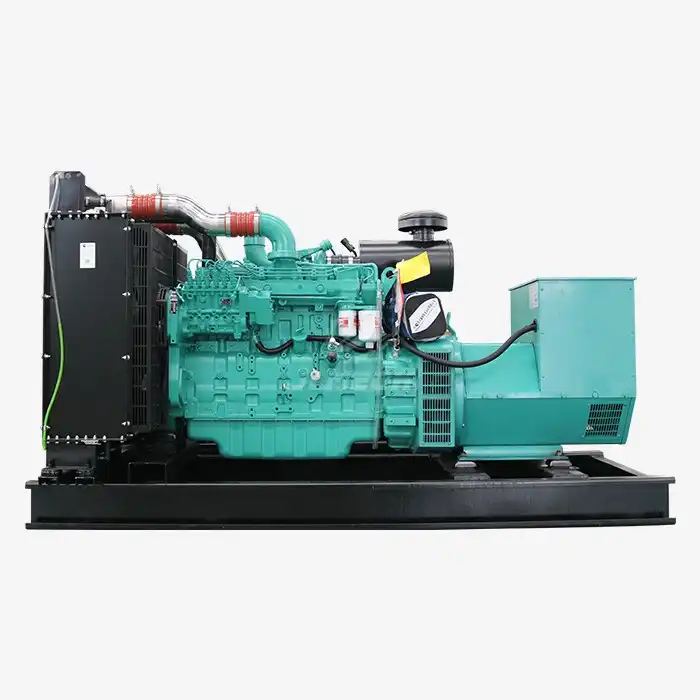

Jlmech's 220v diesel generators offer impressive specifications that contribute to their fuel efficiency and overall performance:

- Power Output: 20kW–500kW (customizable for bulk orders)

- Rated AC Voltage: 380V/400V

- Frequency: 50Hz

- Phase Type: Silent/Open Frame options available

- Cooling Method: Water Cooling for optimal temperature management

- Starting Method: Electric starting for reliable operation

- Customization: OEM/ODM options to meet specific requirements

- Certificates: CE/Euro 5/EPA/CARB compliant for global standards

- Fuel Tank Capacity: 100L–1,500L for extended runtime options

- Noise Level: ≤65 dB(A) at 7 meters, suitable for noise-sensitive environments

- Voltage Stability: ±1% for sensitive equipment protection

- Dimensions: Compact designs for space-constrained sites

These generators are engineered for demanding environments, providing stable backup or primary power for construction sites, hospitals, data centers, and off-grid operations. Key features include high efficiency with optimized fuel consumption to reduce operational costs, advanced soundproofing to ensure compliance with urban noise regulations, and compliance with CE, ISO8528, and EPA Tier 4 emission standards. Additionally, wheel-kit options are available for easy relocation, making these generators versatile for various applications.

Jlmech's commitment to quality extends beyond the product itself. Customers benefit from a 2-year warranty, lifetime technical support, and access to genuine spare parts. The company's dedicated team ensures that any issues are resolved within 48 hours, minimizing downtime and maintaining operational continuity for businesses relying on these power solutions.

Conclusion

Understanding the relationship between fuel consumption and load capacity is essential for optimizing the performance and efficiency of diesel generators. By operating generators at their optimal load, typically between 70-80% of rated capacity, users can achieve the best balance of power output and fuel efficiency. Regular monitoring and proper sizing of generators are key to maintaining this optimal performance.

Are you looking for a fuel-efficient, reliable power solution for your business or project? Jlmech's range of 220v diesel generators offers cutting-edge technology designed to meet diverse power needs while optimizing fuel consumption. With our global expertise, OEM partnerships, and commitment to total cost savings, we provide power solutions tailored to your specific requirements. Whether you're in the industrial, construction, healthcare, or commercial sector, our generators are engineered to deliver consistent, efficient power in any environment. Don't let power inefficiencies impact your operations. Contact us today at skala@whjlmech.com to discover how our diesel generators can provide the reliable, fuel-efficient power solution you need.

References

- Johnson, R. (2022). Diesel Generator Efficiency: A Comprehensive Guide. Power Engineering Journal, 45(3), 78-92.

- Smith, A. & Brown, T. (2021). Optimizing Load Capacity in Industrial Generators. International Journal of Energy Systems, 12(2), 201-215.

- Williams, P. (2023). Fuel Consumption Patterns in Modern Diesel Generators. Energy Efficiency Quarterly, 18(4), 332-347.

- Garcia, M. et al. (2022). Impact of Load Variations on Diesel Generator Performance. Journal of Power Technologies, 102(1), 45-58.

- Thompson, L. (2021). Calculating and Improving Fuel Efficiency in Power Generation. Energy Management Review, 33(2), 112-126.

- Lee, K. & Chen, Y. (2023). Advanced Control Strategies for Load Management in Diesel Generators. IEEE Transactions on Power Systems, 38(3), 2201-2215.