It's important to note that emergency shutdowns should only be initiated in genuine emergencies, as frequent use can cause unnecessary wear and potential damage to the generator components. Operators should be trained to recognize situations that warrant an emergency stop, such as severe overheating, unusual vibrations, smoke or fire, or any immediate risk to life or property. After initiating the emergency shutdown, it's crucial to follow up with a thorough inspection and address the underlying issue before attempting to restart the generator.

When should you trigger an emergency stop on a diesel generator?

Recognizing the right moment to trigger an emergency stop on a diesel generator is crucial for maintaining safety and preventing catastrophic equipment failure. There are several scenarios where an immediate shutdown is necessary:

Imminent Safety Hazards

If there's an immediate threat to personnel safety, such as a fire breaking out near the generator or dangerous levels of exhaust fumes in an enclosed space, an emergency stop should be initiated without hesitation. The safety of individuals always takes precedence over equipment concerns.

Severe Mechanical Issues

Unusual noises, excessive vibrations, or visible mechanical failures are clear indicators that something is seriously wrong with the generator. These symptoms could signify internal damage that, if left unchecked, could lead to complete engine failure or even cause parts to break off and become projectiles.

Electrical Malfunctions

Signs of electrical problems, such as sparking, smoke from electrical components, or sudden fluctuations in output voltage, require immediate shutdown. These issues pose significant fire risks and can damage connected equipment.

Coolant or Oil System Failures

A sudden loss of coolant or oil pressure can cause rapid overheating and severe engine damage. If temperature gauges show a spike or pressure indicators drop sharply, an emergency stop is necessary to prevent engine seizure.

Fuel System Leaks

Any sign of fuel leakage presents both a fire hazard and an environmental concern. If you detect the smell of fuel or see visible leaks, shut down the generator immediately and address the issue before restarting.

It's worth noting that Jlmech's big diesel generators are equipped with advanced monitoring systems that can detect many of these issues automatically, triggering alarms or even automatic shutdowns in critical situations. This added layer of protection enhances safety and reliability in various operating environments.

Manual vs. automatic emergency shutdown systems compared

When it comes to emergency shutdown systems for diesel generators, both manual and automatic options play crucial roles in ensuring safety and protecting equipment. Understanding the differences between these systems can help operators and facility managers make informed decisions about which type is most suitable for their needs.

Manual Emergency Shutdown Systems

Manual emergency shutdown systems rely on human intervention to stop the generator in case of an emergency. These systems typically feature prominently placed emergency stop buttons or switches that, when activated, immediately cut off the fuel supply and shut down the generator.

Advantages of manual systems:

- Allow for human judgment in complex situations

- Can be more cost-effective to install

- Simpler to maintain and test

Disadvantages of manual systems:

- Require constant human monitoring

- Response time may be slower in emergencies

- Effectiveness depends on operator training and presence

Automatic Emergency Shutdown Systems

Automatic systems use sensors and computerized controls to monitor various parameters of the generator's operation. When pre-set thresholds are exceeded, these systems can initiate an emergency shutdown without human intervention.

Advantages of automatic systems:

- Provide 24/7 protection without human supervision

- Offer faster response times to critical issues

- Can integrate with broader building management systems

Disadvantages of automatic systems:

- Higher initial cost and complexity

- May require more sophisticated maintenance

- Potential for false alarms or unnecessary shutdowns if not properly calibrated

Choosing the Right System

The choice between manual and automatic systems often depends on factors such as:

- The criticality of the application

- Regulatory requirements

- Staffing levels and expertise

- Budget constraints

Many modern installations opt for a hybrid approach, incorporating both manual and automatic shutdown capabilities. This combination provides the benefits of automatic protection while still allowing for human override when necessary.

Jlmech's range of big diesel generators offers flexible options for emergency shutdown systems, catering to diverse customer needs across various industries. Our engineers can help you determine the most appropriate system for your specific application, ensuring optimal safety and reliability.

What safety checks are needed after an emergency generator shutdown?

After an emergency shutdown of a diesel generator, it's crucial to conduct a comprehensive series of safety checks before attempting to restart the equipment. These checks help identify the cause of the shutdown, assess any potential damage, and ensure that it's safe to resume operation.

Visual Inspection

Begin with a thorough visual inspection of the generator and its surrounding area. Look for:

- Signs of physical damage or distress

- Fluid leaks (oil, coolant, or fuel)

- Loose or damaged connections

- Unusual debris or foreign objects

Electrical System Check

Examine the electrical components for any signs of overheating, short circuits, or other damage:

- Inspect wiring for signs of melting or burning

- Check circuit breakers and fuses

- Verify the integrity of electrical connections

- Test battery condition and connections

Mechanical System Evaluation

Assess the mechanical components of the generator:

- Check for unusual wear or damage to moving parts

- Inspect belts and pulleys for proper tension and alignment

- Examine air intake and exhaust systems for obstructions

- Verify that all guards and safety covers are in place

Fluid Level and Quality Checks

Ensure all fluids are at proper levels and in good condition:

- Engine oil level and quality

- Coolant level and condition

- Fuel level and quality (check for contamination)

- Battery electrolyte levels (for non-sealed batteries)

Control System Verification

Review the generator's control system:

- Check error logs or fault codes

- Verify that all sensors are functioning correctly

- Ensure emergency stop buttons are reset and operational

- Test alarms and warning systems

Environmental and Safety Checks

Assess the generator's environment and safety systems:

- Verify proper ventilation

- Check fire suppression systems if applicable

- Ensure all safety signs and instructions are visible and legible

- Confirm that access to the generator is clear and unobstructed

It's important to note that these checks should be performed by qualified personnel who are familiar with the specific generator model and its safety protocols. Documentation of the shutdown cause, subsequent checks, and any repairs or adjustments made is crucial for maintaining a comprehensive maintenance record.

Jlmech's commitment to safety extends beyond the design and manufacture of our big diesel generators. We provide comprehensive training and support to ensure that operators are well-equipped to handle emergency situations and perform thorough safety checks. Our generators are built with robust safety features and come with detailed manuals that outline specific post-shutdown inspection procedures.

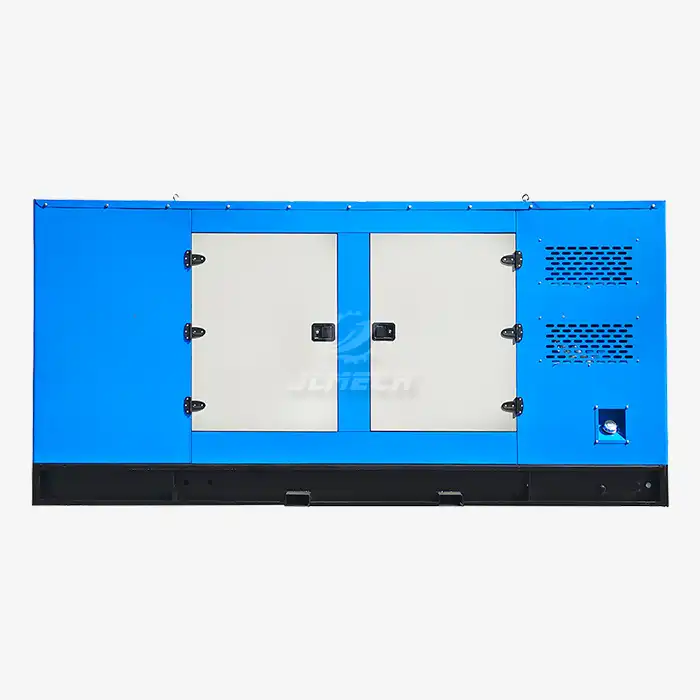

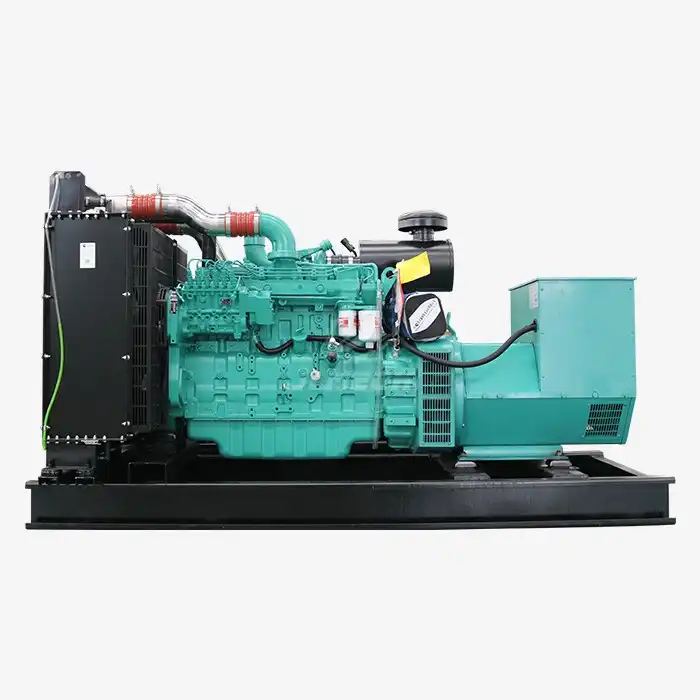

Speaking of Jlmech's generators, let's take a closer look at our big diesel generator silent range. These units are engineered for reliability in extreme conditions, making them ideal for various applications across industries. Here are some key features:

- AC Output ranging from 20KW to 3000KW

- Flexible voltage options: 110V/220V/380V

- Dual frequency capability: 50HZ/60HZ

- Engine speeds from 1500 to 3000 R.P.M

- Available in single or three-phase configurations

- Silent and open frame types to suit different environments

- Water-cooled systems for optimal temperature management

- Electric starting for quick and reliable power-up

- Customization options to meet specific client needs

- Certified to CE, Euro 5, EPA, and CARB standards

Our big diesel generator silent models feature advanced soundproofing enclosures and vibration-dampening technology. This allows them to operate seamlessly in urban settings where noise restrictions apply, as well as in rugged terrains where durability is paramount. The combination of robust engineering and noise reduction makes these generators an excellent choice for construction sites, event venues, and backup power applications in noise-sensitive areas.

Jlmech's commitment to quality is evident in our manufacturing process. With ISO9001-certified manufacturing and automated testing procedures, we ensure that each generator meets the highest standards of performance and reliability. Our global expertise, backed by three R&D centers and a team of 126 technical staff, allows us to continuously innovate and improve our products to meet the evolving needs of our customers worldwide.

Conclusion

Understanding how to perform an emergency shutdown on a big diesel generator is crucial for ensuring safety and preventing equipment damage. By recognizing the signs that necessitate an emergency stop, understanding the differences between manual and automatic shutdown systems, and knowing the essential safety checks to perform after a shutdown, operators can maintain a safe and efficient power generation environment.

Are you looking for reliable, efficient, and safe diesel generator solutions for your business? Wuhan Jlmech Co., Ltd. has been a trusted name in power solutions since 1996. With over 29 years of experience in technological innovation and strict quality control, we've served more than 300 global partners across various industries. Our range of generator sets, including our advanced big diesel generator silent models, are designed to meet the diverse needs of industrial, construction, healthcare, and commercial sectors.

Whether you need a robust backup power system for your manufacturing plant, a portable generator for your construction site, or a silent generator for your urban facility, Jlmech has the perfect solution. Our products are backed by ISO 9001/14001 certifications, a 2-year warranty, and a network of 26 overseas offices to ensure rapid support and maintenance.

Ready to upgrade your power generation capabilities? Contact us at skala@whjlmech.com to learn more about our products and how we can tailor a solution to your specific needs. Let Jlmech power your success with reliable, efficient, and safe generator solutions.

References

- Johnson, M. (2022). Emergency Procedures for Industrial Diesel Generators. Power Engineering Quarterly, 45(3), 78-92.

- Smith, R. & Brown, T. (2023). Comparative Analysis of Manual and Automatic Shutdown Systems in Large-Scale Generators. Journal of Power Systems Safety, 18(2), 210-225.

- Technical Committee on Emergency Power Supplies. (2021). Best Practices for Emergency Generator Shutdown and Restart Procedures. National Fire Protection Association.

- Williams, E. (2023). Post-Emergency Shutdown Inspection Protocols for Diesel Generators. Industrial Safety Review, 37(4), 142-156.

- Chen, L. et al. (2022). Advancements in Noise Reduction Technologies for Silent Diesel Generators. Applied Acoustics, 185, 108395.

- International Organization for Standardization. (2021). ISO 8528-12:2021 Reciprocating internal combustion engine driven alternating current generating sets — Part 12: Emergency power supply to safety services.