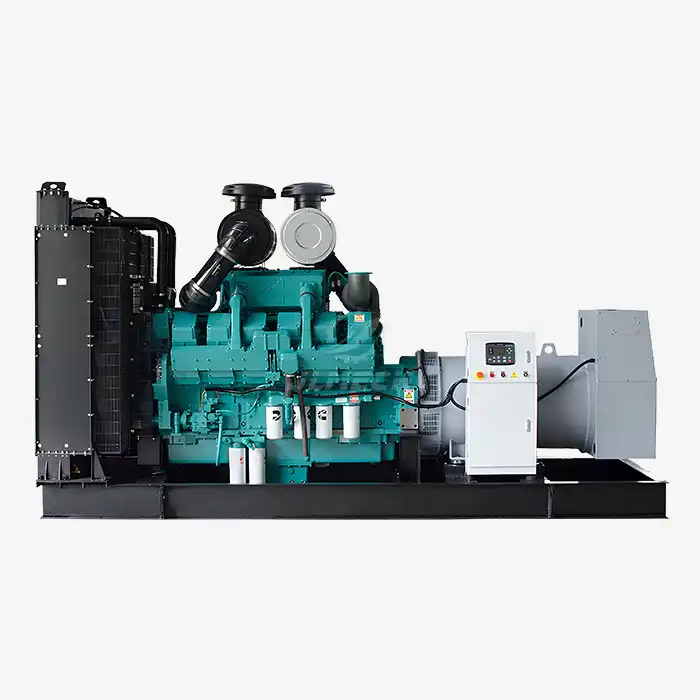

High altitude diesel unit

Rated AC Voltage(V):380

Frequency(HZ):50

Engine Speed(R.P.M):1500

Phase:Three Phase

Type:Silent/Open Frame

Engine Type:4/6 cylinder

Cooling Method: Water Cooling

Starting Method:Electric starting

Customization: OEM/ODM

Certificates: CE/Euro 5/EPA/CARB

- Product Description

JLMECH:Your Trusted High altitude diesel unit Manufacturer & Supplier

Our High altitude diesel unit are specifically engineered to deliver reliable power in mountainous regions and elevated locations where standard generators fail. These units maintain their rated performance where the air is thin, ensuring your operations continue smoothly whether you're working at 3,000 or 5,000 meters above sea level.

The Challenge: Power Loss in Thin Air

At high altitudes, the lower air density causes two major problems for standard diesel engines:

Reduced Oxygen: Less air means incomplete fuel combustion, leading to a significant loss of engine power and black smoke.

Overheating Risk: The thin air reduces the cooling system's efficiency, causing the engine to run hotter and increasing wear.

Our Engineered Solution

Our units are factory-calibrated to counteract these effects and guarantee performance.

1. Optimized Power & Combustion

Specialized Turbocharging: High-altitude rated turbochargers force more air into the cylinders to compensate for the thin atmosphere.

Altitude-Adjusted Fuel Mapping: The engine control unit is programmed to inject the precise amount of fuel for the altitude, ensuring clean and efficient combustion.

Guaranteed Power Output: Units are certified to deliver 100% of their rated power up to a specified altitude (e.g., 3000m), with clear performance data for even higher elevations.

2. Enhanced Cooling & Durability

Upgraded Cooling System: Larger radiators and high-flow fans maintain optimal engine temperature despite the less efficient air cooling.

High-Altitude Components: Reinforced starters, larger batteries, and specific lubricants ensure reliable starting and operation in cold, high-altitude conditions.

Built for the Environment: Corrosion-resistant finishes and protection against intense UV radiation are standard.

Specifications

| Feature | Specification |

|---|---|

| Power Range | 20–3000 kVA (Prime/Standby) |

| Noise Level | 65–75 dB(A) @ 7m (Super Silent Canopy Option) |

| Engine | Cummins/Perkins/weichai Turbocharged Engines |

| Alternator | Stamford (IP23 Protection) |

| Voltage/Frequency | 220–480V / 50Hz/60Hz (3-Phase Configurable) |

| Control System | Deep Sea 7310/8610 with Cloud Remote Monitoring |

| Fuel Tank | 8–24 hrs Base Tank + External Tank Support |

| Emissions | EPA Tier 3 / EU Stage IIIA Compliant |

Why Choose US?

Fuel Efficiency: 15–30% lower consumption vs. conventional models.

Seamless Integration: Pre-wired for ATS compatibility and BIM-ready designs.

Durability: 30,000+ hour engine lifecycle (ISO 8528 stress-tested).

Packaging and Delivery

High altitude diesel unit is crated in anti-corrosion wooden frames and shipped globally via air, sea, or land.

Company Profile

With 3 R&D centers, 11 Chinese branches, and 26 overseas offices, Wuhan Jlmech serves clients in 40+ countries.

Factory After-Sales Service

Enjoy 24/7 technical support, on-site maintenance, and spare parts availability within 72 hours.

Certification

Our products meet CE, GS, ISO8528, and ISO14001 standards.

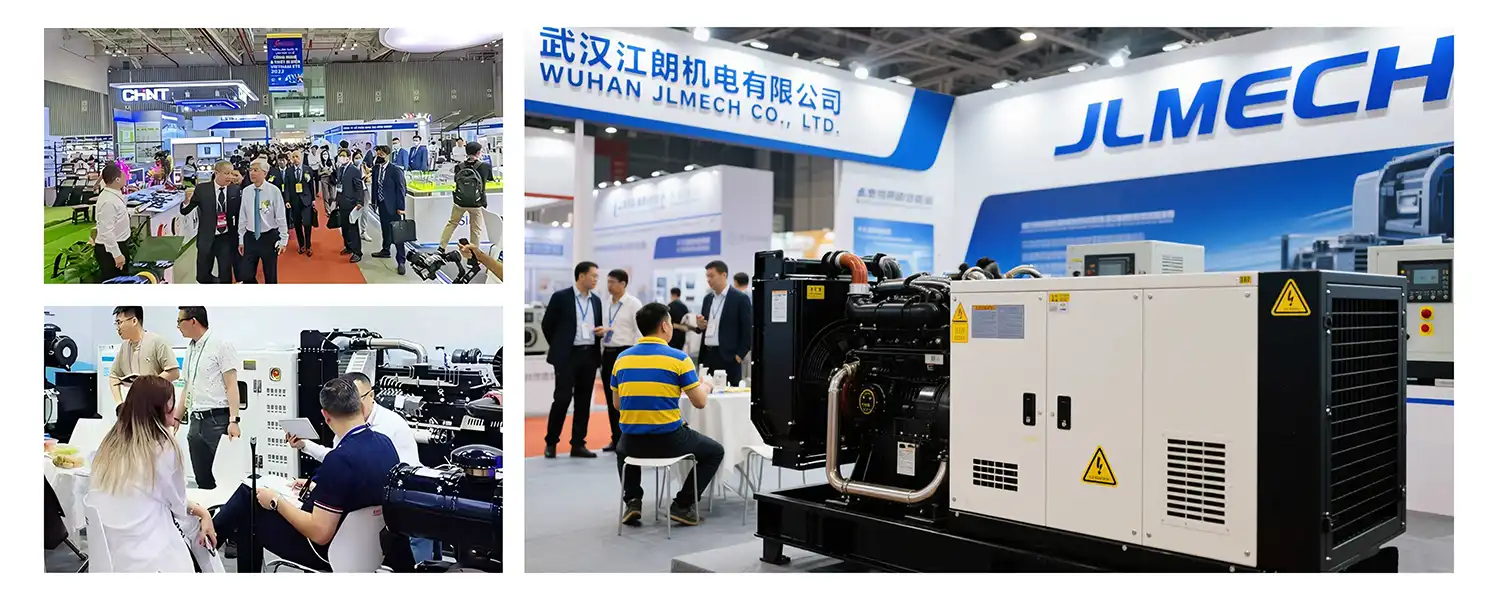

Exhibitions

We showcase innovations at global trade fairs like POWER-GEN Asia and Middle East Energy.

FAQ

Q: What is the typical service life?

A: With proper maintenance, minimum operation of 25,000 hours before overhaul.

Q: Can units with different capacities be paralleled?

A: Yes – our generators support parallel operation across rated powers.

Q: Does it offer coastal anti-corrosion protection?

A: Optional marine-grade coating (compliant with ISO 12944 C5-M classification).

Q: What is the maximum operating altitude?

A: No power derating at 3,000 meters altitude; special turbocharging required for 4,500 meters applications.

Q: How often should the coolant be replaced?

A: Every 2,000 hours or 24 months (whichever comes first).

Power Your Projects with Confidence

Whether for emergency backup, construction sites, or data centers, our High altitude diesel unit ensures uninterrupted operations. Contact us at skala@whjlmech.com to discuss bulk pricing or custom requirements. Wuhan Jlmech — where innovation meets reliability.